Load-Bearing Test of Upward-Sloping Shelf’s Removable Feet

Shelf Dimensions:

Double-sided: 1200*1000*1800 mm

End Frame: 1000*500*1800 mm

Thickness:

layer board: 0.7 mm

Back Panel: 0.5 mm

Bracket: 2.5 mm

Upright: 2.0 mm

Removable Feet: 2.0 mm

Experiment Report: Load-Bearing Capacity of Upward-Sloping Shelf’s Removable Feet

Introduction

In modern warehousing and logistics management, the stability and load-bearing capacity of shelves are critical factors. Especially for shelves with removable feet, their load-bearing capacity directly impacts the safety and longevity of the shelves. This experiment aims to test the load-bearing capacity of the upward-sloping shelf’s removable feet under various load conditions to evaluate their reliability in practical applications.

Experimental Method

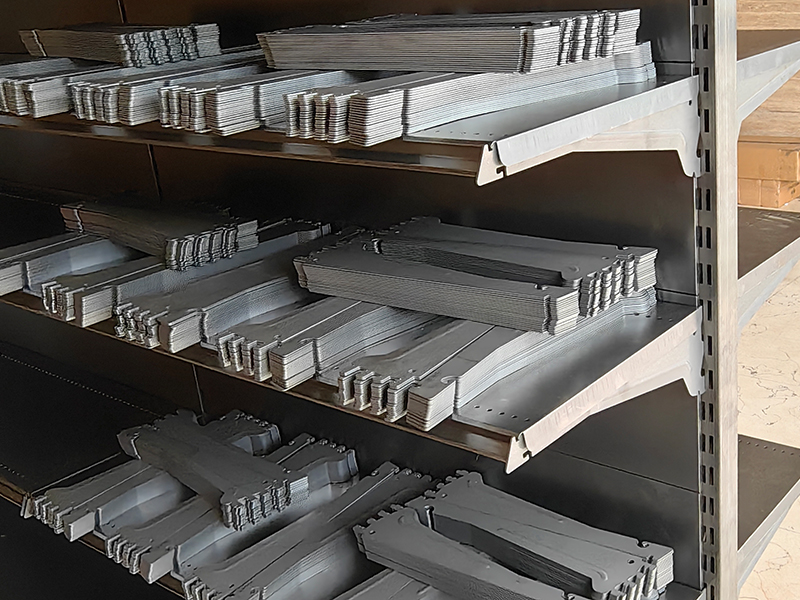

The selected shelf is a five-tier structure on both sides, with each tier holding 9 to 15 stacks of brackets to simulate actual load conditions. The weight calculation for the brackets is as follows: one bracket weighs 0.34 kg, and a stack of 20 brackets weighs 6.66 kg. Each tier starts with a load of 60 kg, increasing by 10 kg increments, and is observed for 10 hours to monitor the condition of the removable feet. The specific load conditions are as follows:

60 kg per tier: 9 stacks of brackets per tier, total weight 600 kg

70 kg per tier: 10.5 stacks of brackets per tier, total weight 700 kg

80 kg per tier: 12 stacks of brackets per tier, total weight 800 kg

90 kg per tier: 13.5 stacks of brackets per tier, total weight 900 kg

100 kg per tier: 15 stacks of brackets per tier, total weight 1000 kg

Additionally, a set of single-side load conditions were tested, with 100 kg per tier on one side, total weight 500 kg, and the other side not loaded to test the stability of the removable feet under single-sided load.

Experimental Process

60 kg Test: Evenly placed 9 stacks of brackets on each tier, total weight 600 kg. Observed for 10 hours, recorded the condition of the removable feet.

70 kg Test: Placed 10.5 stacks of brackets on each tier, total weight 700 kg. Observed for 10 hours, recorded the condition of the removable feet.

80 kg Test: Placed 12 stacks of brackets on each tier, total weight 800 kg. Observed for 10 hours, recorded the condition of the removable feet.

90 kg Test: Placed 13.5 stacks of brackets on each tier, total weight 900 kg. Observed for 10 hours, recorded the condition of the removable feet.

100 kg Test: Placed 15 stacks of brackets on each tier, total weight 1000 kg. Observed for 10 hours, recorded the condition of the removable feet.

Single-Sided 100 kg Test: Placed 15 stacks of brackets on each tier on one side, total weight 500 kg. The other side was not loaded. Observed for 10 hours, recorded the condition of the removable feet.

Experimental Results

Under load conditions from 60 kg to 90 kg, the condition of the removable feet remained good, with no significant deformation or damage observed.

Under the 100 kg load condition, the overall structural stability was not significantly affected.

In the single-sided 100 kg load test, the removable feet showed no significant deformation or damage, and the shelf did not tip over or undergo severe deformation.

Conclusion

The experiment demonstrates that the removable feet of the upward-sloping shelf exhibit good stability and load-bearing capacity under load conditions of 60 kg to 100 kg per tier. In the extreme case of single-sided load, the removable feet also showed no abnormal deformation or damage. Based on this, the design of the upward-sloping shelf is reliable under normal usage conditions. However, it is recommended to avoid prolonged single-sided high load to extend the shelf’s service life